Piano builder strikes new tune with help from igus

31/07/2019

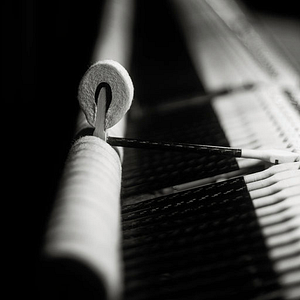

Polymer bearings are centerpiece behind design of unique hammer assembly

An England-based piano builder is striking a new chord in the design of the centuries-old musical instrument by incorporating tribopolymer components from igus in a unique hammer system that offers supreme longevity, climate resistance and improved playability and sound performance.

The components from igus in Phoenix’s D3D Hammer System are two-millimeter roller bearings that are used as center points for the bushless system. The pins offer smooth operation and with approximately a 30 percent increased diameter, are stronger, smoother and more dimensionally precise than traditional wire center pins. Extensive design and 3D printing work with igus allowed Phoenix to create the new hammer system. igus, based in Cologne, Germany, runs its UK operations from Northampton and its North American operations from Providence, R.I.

“These ultra-high-grade pins offer buttery-smooth operation, and with approximately a 30 percent increased diameter, are stronger, smoother and more dimensionally precise than traditional wire center pins,’’ said Phoenix founder Richard Dain. “igus was of the utmost help to us in their selection and provision of material for our hammer flange assemblies.”

Improving the hammer assembly

Dain, an accomplished engineer, pianist and committed patrons to the arts, turned his attention to improving the inherent limitations of the traditional hammer assembly. A piano’s hammer assembly consists of a “hammer flange” – the part that is fixed in place within the overall action – a hinged shank – which defines the flightpath of the hammer – and the hammer itself. The flange, shank and hinge are traditionally made from hornbeam, a type of hardwood that when well finished is very smooth and often compared to ivory.

Although relatively strong, hornbeam is prone to changes in temperature and humidity, like all other woods. It is also difficult to produce with consistent material properties. No two pieces are quite the same. Over time shanks can warp and drift and require regulation adjustments if a piano is to respond uniformly, predictably and with even sound.

No matter how good the regulation of a traditional wooden hammer assembly, the shanks, which are typically about 6 millimeters in diameter and 13 centimeters in length, flex considerably when under the duress of energetic pianism. The hammer wobbles from side to side, and twists chaotically as it is accelerated towards the strings, causing irregular strikes. This chaos gives rise to unpleasant overtones, when the hammer does not contact the strings with precision.

Bushless hinge assembly

The entire system in a traditional wooden assembly suffers from inefficiency due to flexing of the hammer shank. As a remedy, Phoenix chose a complex-weave carbon fiber shank to replace hornbeam. The material is superbly strong and uniform, offering superior, climate-resistant performance throughout the registers of a piano. There is also no increase in weight.

The hinged hammer flange is traditionally made of wood. Phoenix considered a range of materials to replace the flange, with a very specific aim in mind: to create a “bushless” hinge assembly. Traditional bushes are made from cylindrical felt inserts, that provide an interface between metal journals (called center pins) and the wooden parts. They must provide enough “snugness” for the hammer not to wobble from side to side, but must also be sufficiently free from friction for the system not to feel stiff. High friction from a tight bearing will feel like “sluggishness” to a pianist and is another form of energy loss.

When a new hammer flange is correctly bushed, it is by definition already at a critical point with tiny margins of error. As wear inevitably takes its toll on the bushing, looseness impacts the system, causing a loss of fine control over the path of hammer flight, while noises and clicks are prone to develop as the pin rattles against the bushing. Swelling of felt in periods of high humidity cause stiffness and even seizure.

Enormous longevity with the new system

Any noises – no matter how seemingly inoffensive in isolation – can become a nuisance to a sensitive artist, and even more so to a recording engineer. igus, with its unique tribopolymer material, has enabled Phoenix to develop a bushless action. The D3D Hammer System offers all the advantages of a traditional system in prime condition, as well as climate resistance and, what designers at Phoenix confidently predict, enormous longevity. “Indeed, we expect these assemblies may well exceed the lifespan of the piano itself,” Dain said.

Already formulated for industrial bearing applications, the tribopolymer material is perfect for this application for performance and aesthetics. Its ivory-white color perfectly complements the carbon fiber shanks, and black inner felt Abel hammers. Tuning technicians appreciate the cream color, which is easy to see in the confined space of a piano action.

“From building our prototypes we have been able to ream the igus material with relative ease, ensuring a perfect fit for our center pins,” added Phoenix’s James Bacon, who advised on and built the prototype. “Our test piano, which is fitted with a prototype of the D3D Hammer System, offers a fabulous sense of control and immediacy, and superbly controlled hammer flight. Pianists report that D3D is like stepping into a Ferrari after driving a Ford Model T.”

Once acclimatized, pianists find that they can produce more power with less effort, and that they have a sense of connection with the piano that they have never before experienced. “All of us on the Phoenix team are confident that we have not only remedied the age-old limitations with hammer assemblies, but that we have produced a world-beating system that is a joy for pianists to use,” Dain said.

A new era in piano innovation

In the 19th century, there was an explosion of ideas within the piano industry. Reciprocity between piano builders, composers, pianists, patrons and audiences propelled enormous rates of innovation in both instruments and composition, and a variety of design concepts became available, each offering something unique to the world of music.

By the late 19th century piano building had largely converged on a design paradigm that continued throughout the 20th century, amid an atmosphere of increasing reluctance to explore new design concepts. Piano makers shifted their focus towards branding, value engineering and marketing, while innovation, if any, was skewed towards finding cheaper solutions for mass production.

In the absence of improved piano sound, which for 150 years had driven experiment with new styles, came stagnation in composing classical music. New genres of composition followed the same trend of stagnation, so much so that by the middle of the 20th century the future of classical piano came into question for lack of innovative interest.

The defining spirit of Phoenix Pianos is one of recapturing the innovative drive of the 19th century piano builders, specifically in challenging the numerous now-outmoded design limitations found in traditional instruments.

For more information on 3D printing with igus, visit the website:

https://www.igus.com/info/3d-print-motion-plastics-printed