Video of the Week – How igus engineering plastics are being used in the bottling industry

08/04/2020

3rd April, 2020

Although high-performance plastics used to be overlooked as suitable materials for machine components, they are now a standard feature in food processing equipment. But their potential has by no means been exhausted. igus supplies energy chains based on hygienic design guidelines and wear resistant plain bearing components for a wide range of solutions.

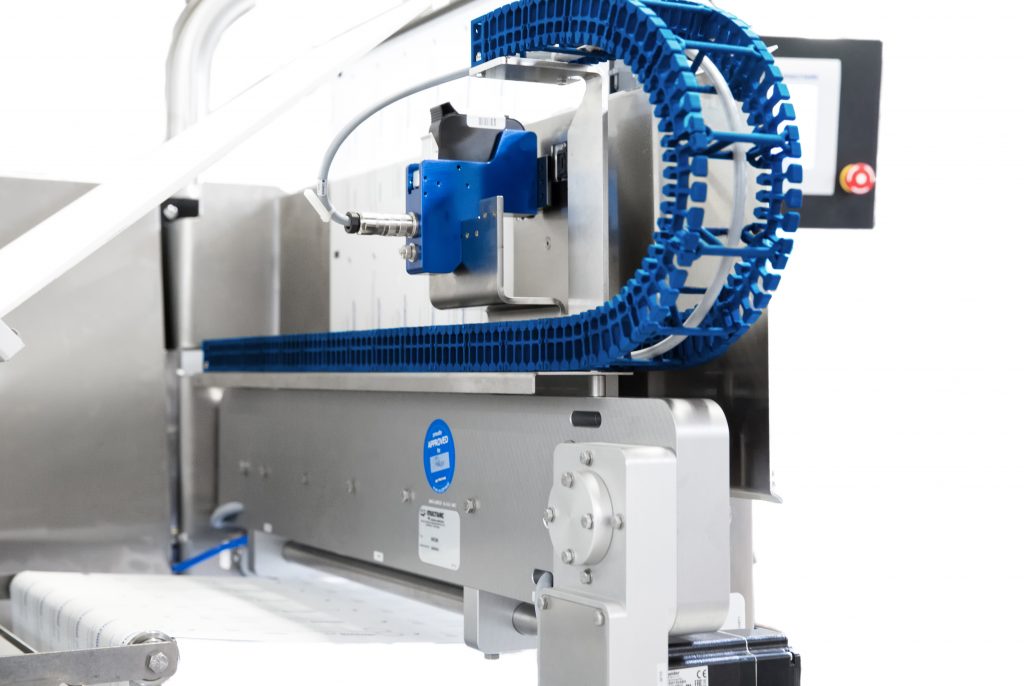

The open design of the TH3 plastic energy chain makes it very easy to clean, while rounded corners and simple, threadless connections prevent dead spaces where debris and germs can build-up. In additional, the structure of the e-chain avoids surfaces rubbing against each other; this prevents abrasion and material shedding. The blue material, which is typical of plastic elements in the food & drinks industry, is FDA/EU-compliant and is highly resistant to aggressive cleaning agents and chemicals.

As well as energy chains, igus offers the blue bearing materials iglidur A160 and iglidur A181, which comply with EU regulation 10/2011 and FDA requirements. iglidur A160 is resistant to chemicals, making it impervious to aggressive cleaning agents. iglidur A181 on stainless-steel shafts, on the other hand, has a low coefficient of friction and is therefore more suited in applications involving pivoting and rotating movements. In addition to plain bearings, igus also supplies both materials as a tribo-tape for lining sliding surfaces, and as plate or bar stock for further machining.

As the safety standards for the protection of consumers are extremely high, the demand for detectable materials in food processing machinery is high. A special high-performance plastic material which can be easily traced with standard metal x-ray machines, is to be found in selected products of the igubal series, as well as in swivel joints and clevis joints, flange bearings, spherical bearings and pillow block bearings.

igus also supplies a wide range of stainless-steel components specially for the food & drinks industry. For conveyor systems, the drylin ZLW toothed belt axis kit is available in various widths and lengths ready-to-install. Except for the toothed belt and the liner, the axis has a very open design and is completely made of stainless steel. An extremely long service life is possible if used in combination with liners made of iglidur E7. FDA-compliant guide rollers are also available, each consists of two xiros ball bearings and one tube.

To enable igus to guarantee service life and make it calculable for all products, the firm carries out extensive testing. The results of which are fed into a database, to drive the online product finders and service life calculators. Engineers are therefore always able to find the most suitable solution that improves the technical performance of their equipment.

To watch the video, please follow this link: https://youtu.be/v_E2JKTKU20

For more information about the extensive range of component and systems targeting the drinks industry, please visit: www.igus.co.uk/beverage or call igus on: 01604 677240

The terms igus, Apiro, chainflex, CFRIP, conprotect, CTD, drylin, dry-tech, dryspin, easy chain, e-chain, e-chain systems, e-ketten, e-kettensysteme, e-skin, flizz, ibow, igear, iglidur, igubal, kineKIT, manus, motion plastics, pikchain, plastics for longer life, readychain, readycable, ReBeL, speedigus, triflex, robolink, and xiros are protected by trademark laws in the Federal Republic of Germany and internationally, where applicable. All other registered trademarks and trademarks are the property of their respective owners.