New energy chain system for intralogistics and crane systems designed by motion plastic experts igus

20/10/2020

Energy and data transmission rolled out and connected in under 60 minutes

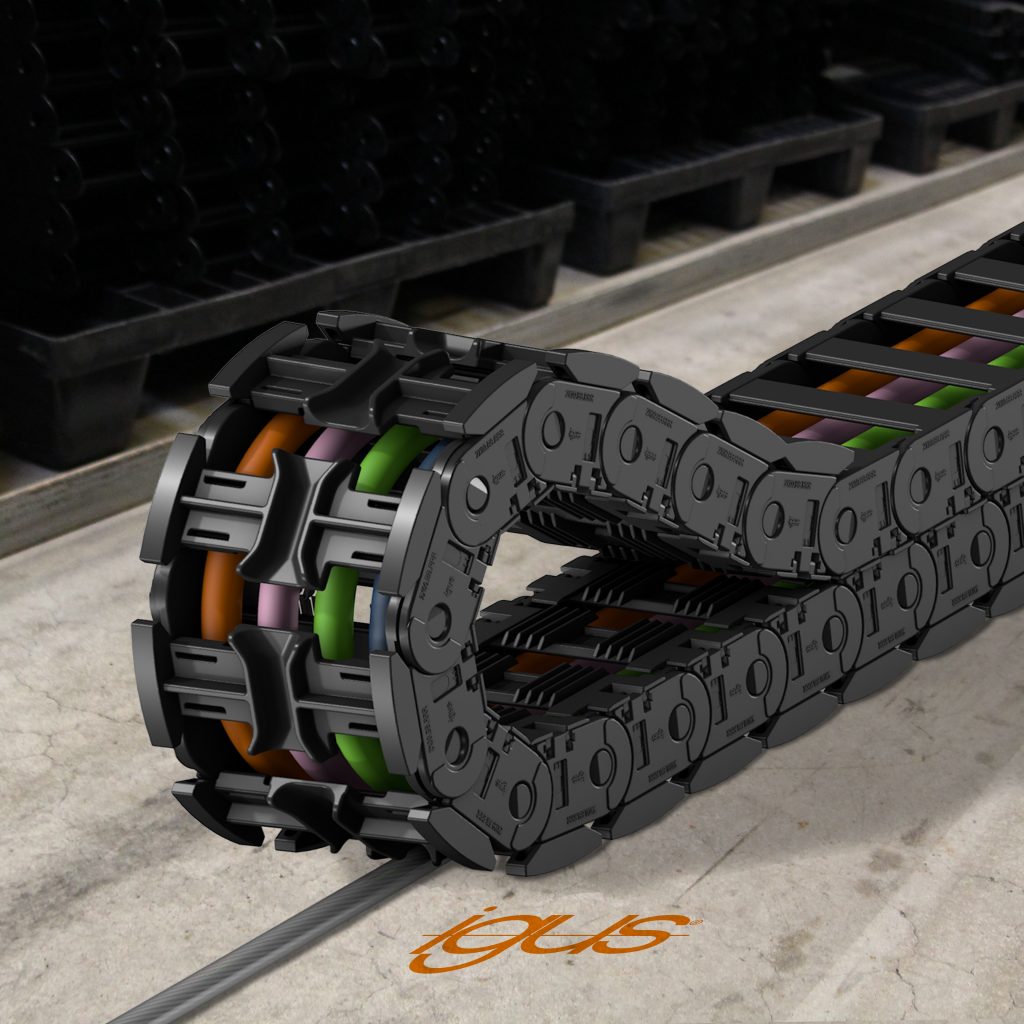

A new energy chain system for intralogistics and crane systems has been designed by motion plastic experts igus.

The company, whose UK headquarters are in Northampton, has designed and manufactured the ‘autoglide 5 system’, a unique product which guides energy safely, for long distances and at a low cost.

Justin Leonard , the e-chain Director at igus UK, said: “Traditionally, companies have relied on busbar systems to transmit power and data in tight, compact spaces, and in situations where fast lane movements are required, such as storage and retrieval units.

“These are expensive to maintain, can only be used for standard levels of power transmission and have to be maintained regularly to avoid contact faults.

“These shortfalls inspired our design team to look at an alternative. Instead of relying on a guide trough the new igus autoglide 5 system lies on a steel wire rope and is held in place by a recess in the e-chain. It can safely guide horizontal cables at speeds of up to 4metres per second and up to 80 metres in distance. It is also maintenance-free and easy to install – with an 88% shorter installation time compared to trough systems.”

The igus autoglide 5 system can be used to manage energy, data, liquids, and air. It is ideally suited for crane systems and intralogistics, a term that refers to warehouse logistics, the movement of materials and goods and their corresponding information and documentation.

Guide energy and data safely even without a trough

To install the autoglide 5 system the installer should lay the supplied metal guide rope along the aisle floor. It is also possible to use a plastic rope or a profile.

The underside of the chain links has a recessed guide section in the centre, enabling the energy chain to rest safely on the rope.

This system consists of comb-like injection-moulded crossbars. These prevent the energy chain from sliding and means a guide trough is not required.

igus offers the autoglide 5 system already fully harnessed as a readychain with highly flexible chainflex cables.

Long-lasting, maintenance-free, and easy to clean

Busbar systems, or the contacts of a pantograph, are susceptible to wear and often need be replaced after only one or two years. The igus autoglide 5 system though, made of high-performance polymers, is durable and maintenance-free. Unlike the busbar system it has no open contacts, so the aisle is also easy to clean.

igus is currently testing the service life of the new energy chain in its own 3,800 square metre test laboratory.

Find out more about this new igus product HERE.

The terms “igus”, “Apiro”, “chainflex”, “CFRIP”, “conprotect”, “CTD”, “drylin”, “dry-tech”, “dryspin”, “easy chain”, “e-chain”, “e-chain systems”, “e-ketten”, “e-kettensysteme”, “e-skin”, “e-spool”, “flizz”, “ibow”, “igear”, “iglidur”, “igubal”, “kineKIT”, “manus”, “motion plastics”, “pikchain”, “plastics for longer life”, “readychain”, “readycable”, “ReBeL”, “speedigus”, “triflex”, “robolink”, “xirodur”, and “xiros” are protected by trademark laws in the Federal Republic of Germany and internationally, where applicable