Advancing research: igus joins global automation body PROFIBUS & PROFINET International (PI)

10/11/2020

igus has joined the world’s largest automation membership body to advance the research of Profinet technology in dynamic applications.

The focus for PROFIBUS & PROFINET International (PI), which has more than 1,700 members worldwide, is the continuous development of Profibus and Profinet technology, the two most important enabling technologies in automation today.

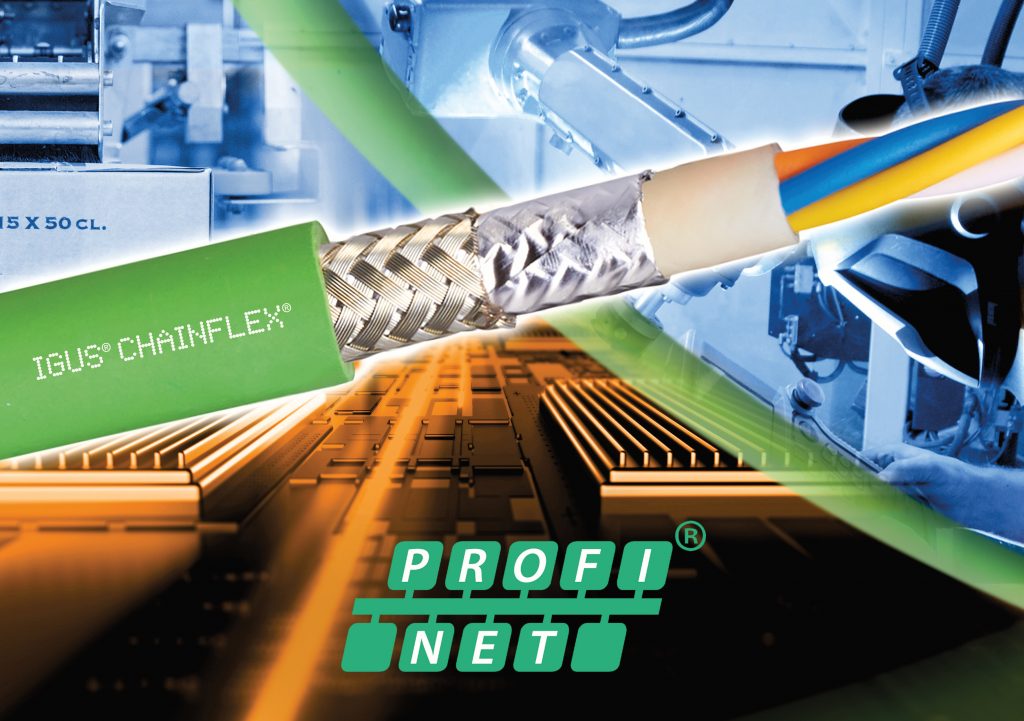

igus, which has its UK headquarters in Northampton, has embraced Profinet technology, with its chainflex cable range offering nine different Profinet cable types, all specifically developed for continuous movement in an energy chain.

John Barker, Chainflex product manager at igus, the global manufacturer of energy chain systems and polymer plain bearings, said: “Profinet is increasingly important in dynamic applications so we are delighted to have joined PI as a global cable manufacturer. We are committed to further advancing the development of this exciting technology, ensuring our customers benefit from cable solutions that always meet existing and new electrical requirements. “

Profinet, the world’s leading Ethernet-based communication solution for industrial automation, offers clear advantages for industry: a large amount of data can be transferred at up to 100 Mbit/second based on the Ethernet protocol.

This technology can prove challenging for standard cables when used in a moving machine, especially where space is restricted. For this reason, igus has been developing cables that are specifically suitable for use in energy chains and on robots for more than 25 years.

Whether linear movement or torsion, the cable is guaranteed to last

At igus you can choose between nine different cable qualities depending on your requirements and environment. The igus chainflex Profinet cables are available in four jacket materials, four bend radii and two torsion angles.

The igus product range offers solutions for small installation spaces, high speeds and three-dimensional movements (with up to ±360 degrees/m on a robot or in free space)

All chainflex cables are subject to the same quality standards, are available in any length, and undergo an extensive series of tests in the company’s dedicated 3,800 square metre test laboratory. There, for example, the Profinet cable CFBUS.LB.060 has completed over 65 million strokes at a bend radius of 63mm.

Due to rigorous research and testing the igus chainflex cables have a unique 36-month functional guarantee. Upon request, they are also available fully harnessed as readycable, for example with an M12 round Telegärtner connector.

For more information on Profinet technology and chainflex Profinet cables visit: https://www.igus.co.uk/info/unharnessed-cables-profinet

The terms “igus”, “Apiro”, “chainflex”, “CFRIP”, “conprotect”, “CTD”, “drylin”, “dry-tech”, “dryspin”, “easy chain”, “e-chain”, “e-chain systems”, “e-ketten”, “e-kettensysteme”, “e-skin”, “e-spool”, “flizz”, “ibow”, “igear”, “iglidur”, “igubal”, “kineKIT”, “manus”, “motion plastics”, “pikchain”, “plastics for longer life”, “readychain”, “readycable”, “ReBeL”, “speedigus”, “triflex”, “robolink”, “xirodur”, and “xiros” are protected by trademark laws in the Federal Republic of Germany and internationally, where applicable.