Compact rotation: igus expands range of slewing rings for tight spaces

29/06/2021

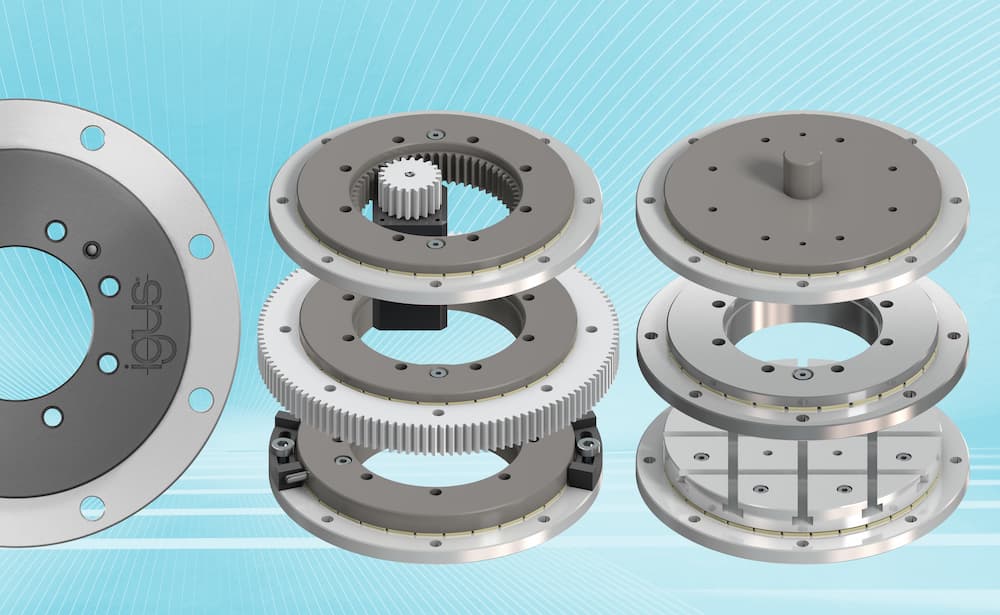

The space-saving PRT-04 slewing ring bearings are now available in a range of sizes with inner and outer tooth drives and a locking function.

Compact and lightweight, the new bearings have been developed specifically for movement in tight spaces and give igus an entire PRT-04 modular system. The lubrication-free, slewing ring bearing system comes in eight sizes and features an outer tooth drive and angle stop (optional), and now also inner drive teeth and a locking function. This allows the design engineer to find the right bearing product for applications with very little installation space.

igus slewing ring bearings rotate assembly units, control panels and indexing tables, even at high speeds. For them to turn while remaining maintenance-free, igus uses sliding elements that work radially and axially between the bearing’s inner and outer faces. These slides, that are made of the high-performance polymer “iglidur J”, ensure that friction and wear are minimised without lubrication.

Introduced as a new product in 2019, igus is now launching an entire modular system for the PRT-04 ring bearing range. The corrosion-resistant slewing rings have been developed specifically for use in tight installation spaces and for loads of up to 48KN. The PRT-04 range requires only half the space the PRT-01 needs, is 60% lighter and costs 20% less. Several strong arguments have shown customers the merits of the new range. “The PRT-04 slewing ring bearings allowed us to implement several applications in automation technology in the packaging industry and furniture technology”, says Dean Aylott, Product Manager for the PRT business unit at igus UK. “The series has now been expanded so that design engineers can have even greater design freedom.”

Compact drive with inner drive teeth and new locking function

The compact, lightweight slewing rings are available in eight sizes from 20 to 300 millimetres. In addition to standard accessories such as drive pins, variable mounting plates and clamping levers, igus offers three outer drive ring systems and one inner drive ring for very tight installation spaces, such as in automated transport systems. The slewing ring bearings are driven with drive belts or gears that igus manufactures by injection moulding highly wear-resistant tribo-polymers.

igus has also developed a slewing ring bearing with a locking function specifically for applications such as assembly tables. The locking points are either fixed at 90° or can be defined according to customer requirements. For specific applications, igus supplies a slewing ring bearing version with dissipative sliding elements to prevent electric charge in an ESD-compliant manner. As with all igus products, the service life of the slewing ring bearings can also be calculated online for each application.

Learn more about igus slewing ring bearings: https://www.igus.co.uk/info/slewing-ring-bearings

The terms “igus”, “Apiro”, “chainflex”, “CFRIP”, “conprotect”, “CTD”, “drygear”, “drylin”, “dry-tech”, “dryspin”, “easy chain”, “e-chain”, “e-chain systems”, “e-ketten”, “e-kettensysteme”, “e-skin”, “e-spool”, “flizz”, “ibow”, “igear”, “iglidur”, “igubal”, “kineKIT”, “manus”, “motion plastics”, “pikchain”, “plastics for longer life”, “readychain”, “readycable”, “ReBeL”, “speedigus”, “tribofilament“, “triflex”, “robolink”, “xirodur”, and “xiros” are protected by trademark laws in the Federal Republic of Germany and internationally, where applicable.