Maximum precision: new drylin linear bearings for round shafts

06/07/2021

New bearings made of iglidur W360 high-performance plastic ensure precise and easy linear movements

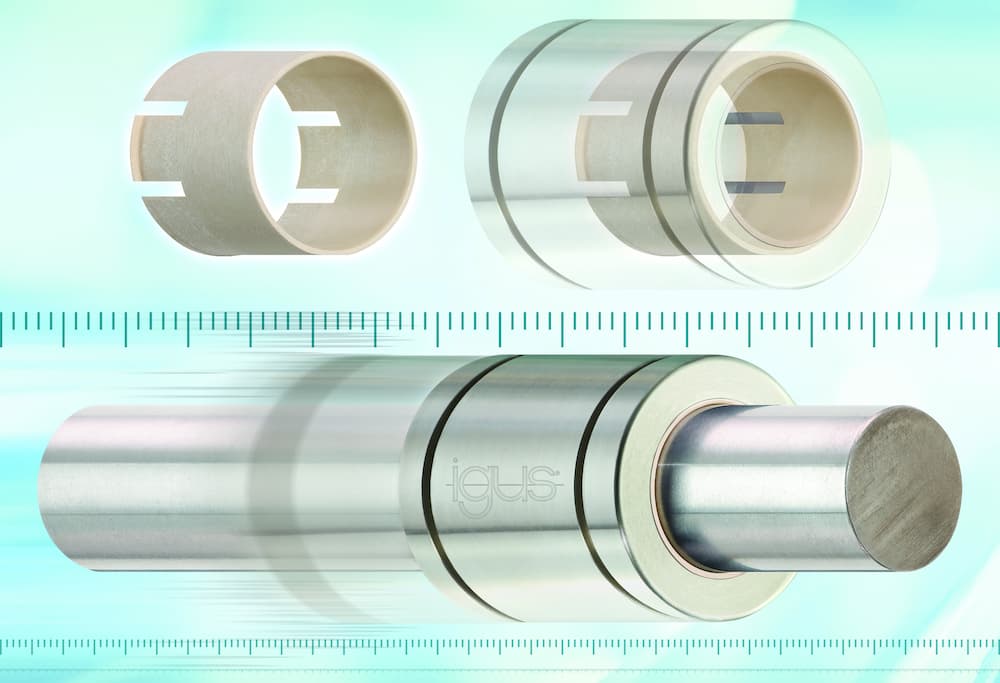

The new iglidur W360CM series linear bearings are designed to slide on round shafts with high precision. The linear bearing consists of an aluminium housing and a polymer liner, which ensures high accuracy. The design allows precise movement. By using iglidur W360 high-performance polymers, no external lubrication is needed. The dimensions of the new bearings are interchangeable with metallic linear ball bearings, so that they can be easily converted to a 1:1 ratio providing the correct technical considerations are observed.

Linear bearings are used everywhere where goods or objects are moved from A to B, or in adjusting devices or machines. An important reason why motion plastics specialist igus developed the W360CM linear plain bearing series is that high precision motion is a key requirement in, for example, microscopes and X-ray machines. These bearings ensure maximum precision and reliability on drylin R-series round shaft guides.

The long-lasting sliding elements of the bearing are characterised by a thin wall and high strength. They are manufactured using injection moulding from the high-performance polymer, iglidur W360. The bearing can operate in a temperature range between 0ºC-50ºC. Due to the thinner wall design, higher material strength and reduced elasticity, the linear bearings ensure a low operating bearing clearance. These new bearings, like all igus plain bearings and linear bearings, are free of lubrication and thus free from contamination and maintenance

New polymers pass the test

The W360CM linear bearings can be easily mounted in all drylin housings as well as in all standard designs for linear ball bushings. For example, ball-based solutions can be converted 1:1 with the maintenance-free solution without the design wall. The construction of the new linear bearings is simple: the sliding inserts are pressed into the housing until a pre-tensioned snap hook fits into a groove, so the liners are secured and do not come free even under high loads and temperatures. The new drylin R-series was also convincing in tests at igus’s 3,800 square metre laboratory in Cologne, Germany. Using mandrel measurements to check the bearing clearance and precision, it was shown that the bearings of the W360CM series perform much better than coated linear bearings.

The terms “igus”, “Apiro”, “chainflex”, “CFRIP”, “conprotect”, “CTD”, “drygear”, “drylin”, “dry-tech”, “dryspin”, “easy chain”, “e-chain”, “e-chain”, “e-chain systems”, “e-skin”, “e-spool”, “flizz”, “ibow”, “igear”, “iglidur”, “igubal”, “kineKIT”, “manus”, “motion plastics”, “pikchain”, “plastics for longer life”, “readychain”, “readycable”, “ReBeL”, “speedigus”, “triflex”, “robolink” and “xiros” are legally protected trademarks in the Federal Republic of Germany and possibly also internationally.