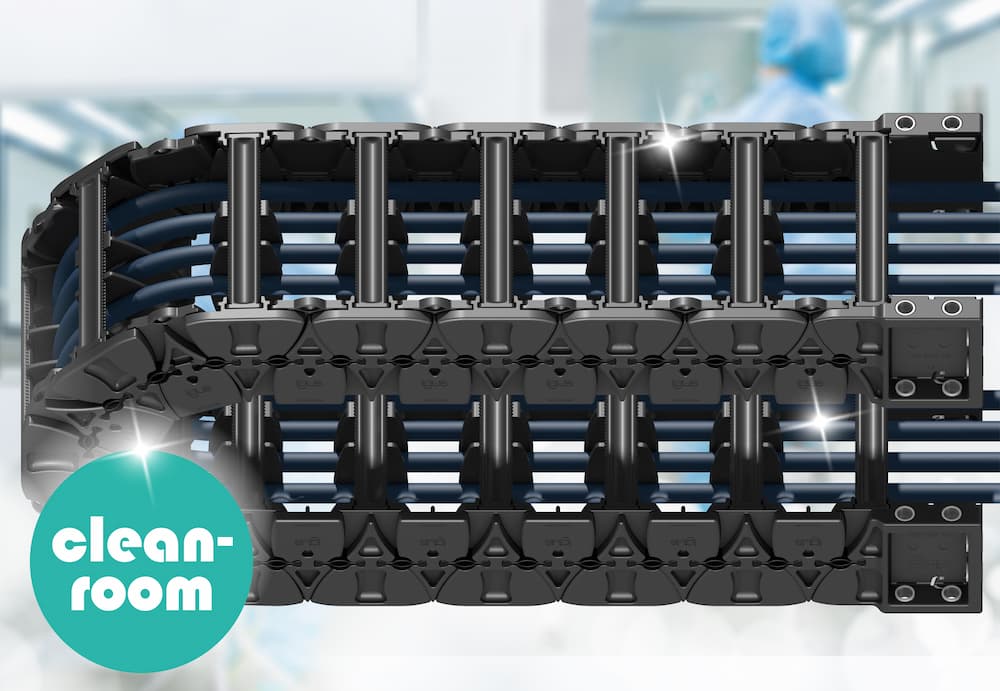

e-chain C6: New design with abrasion-optimized materials for cleanrooms

28/07/2021

igus launches a new design of a particle-free and lightweight energy guide for clinical environments

High abrasion resistance is crucial for machine elements in cleanrooms. In response, igus has developed the C6, an energy chain that is designed to meet the highest cleanroom class. The new chain is specially designed for longer unsupported applications on machines and is based on the successful igus E6 and E6.1 cleanroom series. A new type of connector system as well as the use of a specially tribologically optimized high-performance plastic makes this chain design even quieter, lighter, more installation-friendly and virtually particle-free when in motion.

Regarding the energy chain’s name, “C6“, the “C” stands for its location: a cleanroom, and “6” represents the number of individual parts per chain link. igus has developed the new energy guide based on the success of its globally popular energy chain series E6 and E6.1, optimizing it for this application.

Cables and hoses housed in the new system will be guided on medium travel lengths in clean rooms found in electronics manufacturing, the semiconductor industry, medical facilities, and even pharmaceutical production, as well as in packaging machines, where abrasion-resistance and smooth running is essential. igus has developed a new connector system of individual chain links, making the e-chain light and easy-to-install, and at the same time strong and vibration-resistant.

“We have reduced the contact area to a minimum when moving the C6, so we can ensure extremely low abrasion and a smooth run,” explains Justin Leonard, Director of e-chains in the UK. “In addition, with our knowledge of plastics, we have developed a new material specifically for all areas that come into contact with the cables. The chain is also designed to minimize friction.” The new design is much lighter, saving up to 26% weight compared to the previous E6 series.

C6 should meet the highest cleanroom class

The idea for the C6 was developed in cooperation with a large electronics manufacturer and Fraunhofer IPA, a consultancy division of Germany’s technology innovation centre the Fraunhofer Institute. “We are pleased to be able to try out and develop the chain directly with the experts from industry and cleanroom research,” says Leonard. Test series with the new e-chain are currently running in the in-house cleanroom laboratory in Cologne. “The first tests show the high abrasion resistance of the chain, and we are very optimistic that it will also receive cleanroom Class 1,” says Leonard. “With the design of the C6, we are also prepared for future cleanroom requirements that will require even fewer particles than ISO Class 1.”

Learn more about the new C6: https://www.igus.co.uk/info/echain-c6

The terms “igus”, “Apiro”, “chainflex”, “CFRIP”, “conprotect”, “CTD”, “drygear”, “drylin”, “dry-tech”, “dryspin”, “easy chain”, “e-chain”, “e-chain systems”, “e-ketten”, “e-kettensysteme”, “e-skin”, “e-spool”, “flizz”, “ibow”, “igear”, “iglidur”, “igubal”, “kineKIT”, “manus”, “motion plastics”, “pikchain”, “plastics for longer life”, “readychain”, “readycable”, “ReBeL”, “speedigus”, “tribofilament“, “triflex”, “robolink”, “xirodur”, and “xiros” are protected by trademark laws in the Federal Republic of Germany and internationally, where applicable.