Ready-to-install energy chains fitted more easily, quickly and precisely

31/01/2024

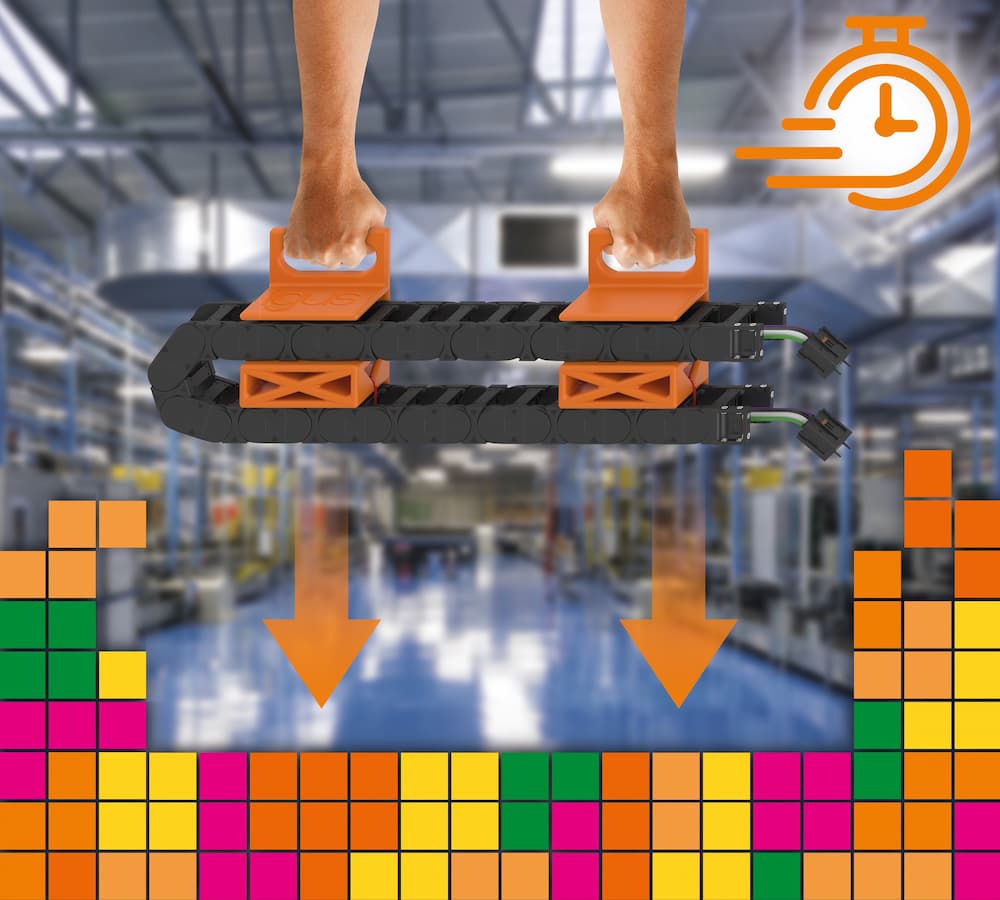

Save installation time and improve handling: igus’s popular readychain service is complete with a new “assembly helper” device: the “fastpositioner”

Idle machines and systems cost manufacturing companies valuable time and money. To make it easier for customers to install energy supply systems and reduce installation time, igus’s readychain service offers pre-assembled cable systems consisting of chain, cables, connectors and other components. What’s special about igus is that customers get everything from a single source.

Readychain means the energy chain is fully populated, assembled with plugs, tested and delivered ready for connection – plug and play. Now igus has made it easier than ever to install ready-to-go e-chains with a new “assembly helper” product: the “fastpositioner”.

Efficient workflows and solutions that save time and resources in operating machines are important in today’s fast-paced, cost-conscious world. “That’s exactly why we offer our readychain service,” says Justin Leonard, director at igus UK. A ready-to-install chain gives customers a clear advantage, for example by supplying a complex e-chain cut precisely to length and assembling and testing the cables. Assembly time is also reduced, which increases productivity. “It is important to us to not just deliver a product, but a complete solution,” says Leonard. “We want to actively improve the customer’s upstream and downstream processes. That’s why we have now added a simple tool to our service, one that offers great added value: the fastpositioner.”

The device makes the handling and precise positioning of ready-to-connect energy chain systems easier, safer and faster. igus supplies the readychains with the fastpositioner in the preset installation position. The customer simply unpacks, positions, and releases the fastpositioner – often supplied as a pair –and the e-chain is ready to connect. There is no need for other position aids, nor for double handling by multiple people. It simplifies handling during assembly and shortens the installation time.

Individual and sustainable solution

Leonard adds, “We make the individual parts using 3D printing. They are precisely adapted to the customer’s requirements, including individual colour selection and imprints as an identification aid”. Fastpositioners can be easily placed between the upper and lower parts of an energy chain and fixed with cable ties, and they are just as easy to remove after placement. The plastic material is regranulate and can therefore be recycled. Also, the fastpositioner can be made from sustainable materials such as corn starch, making the device robust and light, rust-proof and compostable – depending on the specific material.

Complete solution from a single source

The igus advantage is that customers get everything from a single source. Design, production and packaging all take place on site at igus, enabling short lead times and fast delivery. As the latest addition to the readychain service, the fastpositioner is not only a carrying handle, it also serves as a fixing device or “jig”, ensuring the chain is always in the optimal position for installation. “This tool shows customers that we offer a well-thought-out solution from start to finish,” Leonard concludes.