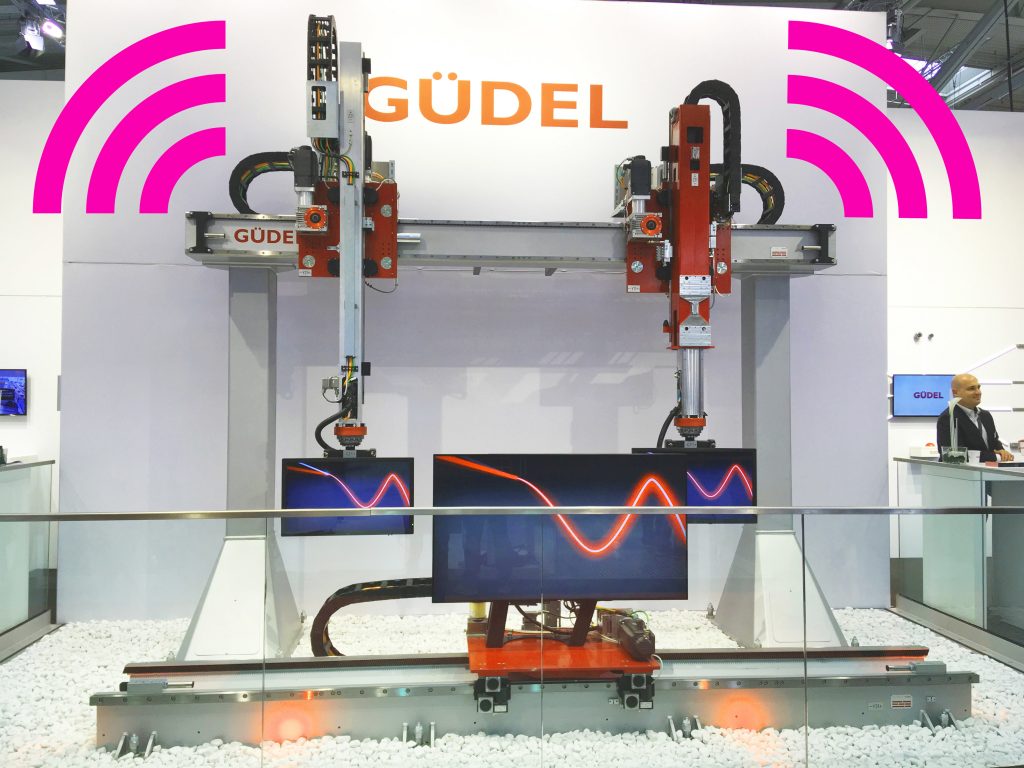

Güdel linear robot, even more productive with intelligent energy supply

15/07/2020

igus energy chain sensors, monitors movement and measures wear

15th July, 2020

Plan maintenance in advance: the igus intelligent smart plastic e-chains, cables, and plain bearings can assist with this. Now, manufacturers of machines and systems are also offering solutions with their own condition monitoring. Among them is the Swiss company Güdel: the automation specialist uses the igus e-chain sensors EC.M and EC.W in their linear robots. “The sensors measure the movement and wear of the four energy chains used and send the measured values via the icom data collector to Güdel’s condition monitoring computer”, explains Richard Habering, head of the smart plastics division at igus. By connecting to the igus cloud, the data is evaluated using AI and machine learning. The integration of the analysed data takes place via the Güdel Condition Monitoring System. “With this tool, the user can monitor the status of the energy chains and rollers in use”, says Daniel Bangerter, head of customer care at Güdel. “Maintenance can be planned by collecting and evaluating the data.”

For further information on igus smart plastics and preventative maintenance visit www.igus.co.uk/smartplastics

The terms “igus”, “Apiro”, “chainflex”, “CFRIP”, “conprotect”, “CTD”, “drylin”, “dry-tech”, “dryspin”, “easy chain”, “e-chain”, “e-chain systems”, “e-ketten”, “e-kettensysteme”, “e-skin”, “e-spool”, “flizz”, “ibow”, “igear”, “iglidur”, “igubal”, “kineKIT”, “manus”, “motion plastics”, “pikchain”, “plastics for longer life”, “readychain”, “readycable”, “ReBeL”, “speedigus”, “triflex”, “robolink”, “xirodur”, and “xiros” are protected by trademark laws in the Federal Republic of Germany and internationally, where applicable.