igus 3D printing service: low-wear polymer parts in 5 days!

18/08/2020

18th August, 2020

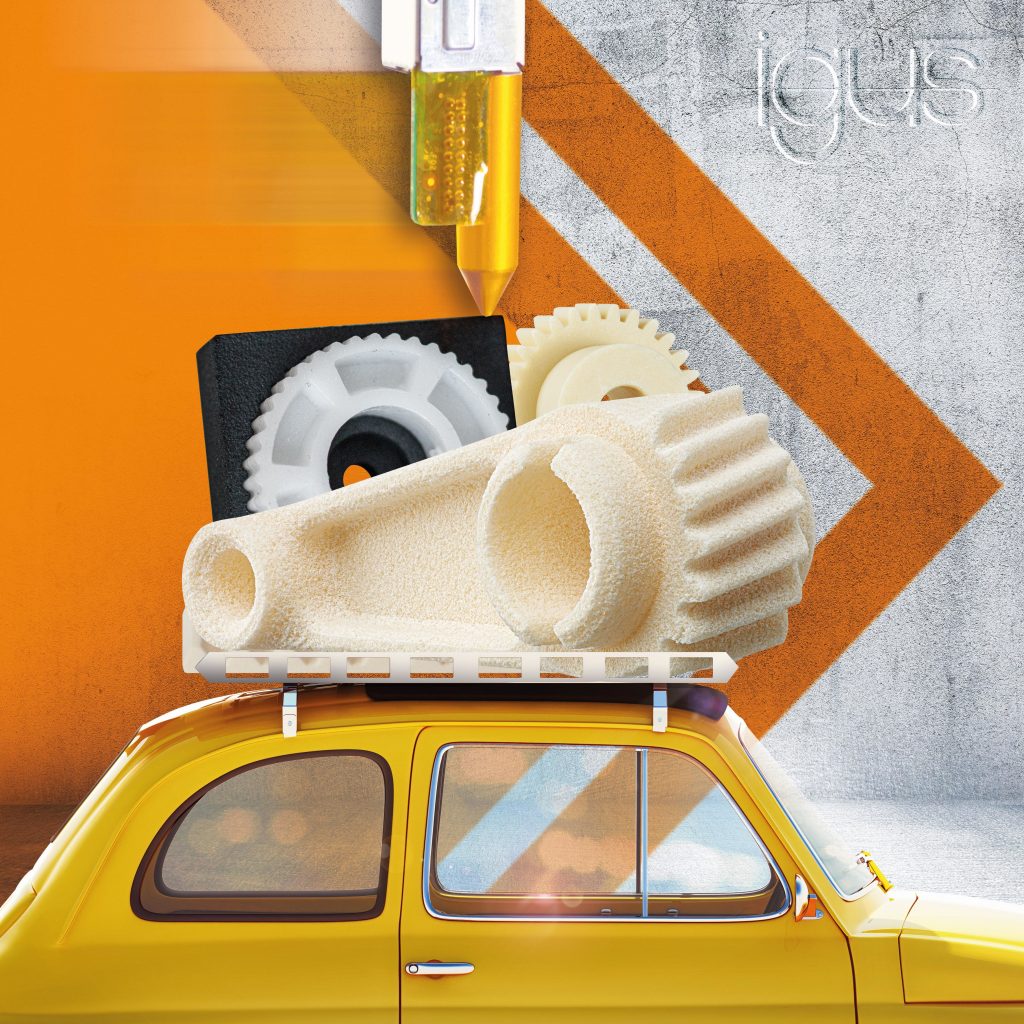

Production-ready, long-lasting special parts from a 3D printer, increase design freedom in the automotive industry

Additive manufacturing gives designers new freedom and flexibility in the design of special solutions, including the development of efficient vehicle components. If lightweight and durable wear-resistant parts are required, igus offers a solution from their 3D printing service. Users can order a special part made of tribologically- optimised polymers from igus online in just a few seconds.

A quick response time and customised design are paramount in the automotive industry design teams. The industry needs partners who can deliver special solutions in small quantities, cost-effectively, fast, and by responding to new requirements to create a competitive advantage in the automotive market. The expanded 3D printing service from igus is particularly suitable for the short-term production of wear-resistant parts. The motion plastics specialist uses 3D printing to cost-effectively produce prototypes or batches within a very short time. The main advantage of additive manufacturing: the designer has maximum freedom in the design of the component, without having to invest in expensive steel tools with long lead times. igus manufactures the solutions from their highly wear-resistant iglidur tribo-polymers. Tests in the igus laboratory show that they are up to 50 times more abrasion-resistant than standard polymers and are comparable to injection moulded parts in terms of wear resistance. They are both lightweight and quiet in motion – important criteria in vehicle design. Printed solutions from igus are already being used in turbochargers, as pivoting bearings in suspension systems and for a special accelerator mechanism.

print2mold process ensures the free choice of materials

In the igus3D printing service, the user can choose between different manufacturing processes: they can either manufacture their component using the laser sintering process, with iglidur I3, iglidur I6 and I8 ESD tribo-polymers or alternatively using twelve different filaments using the FDM process. For the individual component to be made from the ideal iglidur material for the respective application, igus also offers the print2mold process. An injection moulding tool is printed for the special solution and is then used in the injection moulding machine. This allows the designer to make use of the total iglidur material range of 55 tribo-polymers.

Wear-resistant components requested online

The way to a lubrication-free special solution is very simple: click on the link https://iglidur-designer.igus.tools/upload, upload the STEP file of the component and select the appropriate material. The price for production (in the print2mold process including the costs for the injection moulding tool) as well as information about the material, precision and flexural strength are shown online. After selecting the appropriate tribo-polymer, the user can enter the quantity and request either a quotation or order the parts. The additively manufactured special parts are shipped 5 days after the order has been placed. In the case of the print2mold process, the injection-moulded parts are ready for shipping approximately 10 business days after the order has been confirmed.

The terms “igus”, “Apiro”, “chainflex”, “CFRIP”, “conprotect”, “CTD”, “drylin”, “dry-tech”, “dryspin”, “easy chain”, “e-chain”, “e-chain systems”, “e-ketten”, “e-kettensysteme”, “e-skin”, “e-spool”, “flizz”, “ibow”, “igear”, “iglidur”, “igubal”, “kineKIT”, “manus”, “motion plastics”, “pikchain”, “plastics for longer life”, “readychain”, “readycable”, “ReBeL”, “speedigus”, “triflex”, “robolink”, “xirodur”, and “xiros” are protected by trademark laws in the Federal Republic of Germany and internationally, where applicable.